What is CNC Machining?

Manufacturing operations from countless industries have been revolutionized by CNC machining. CNC stands for Computer Numerical Control and is a method whereby material such as metal, plastic, wood, and even composites are quickly and precisely turned from raw blanks into finished parts with tight tolerances. This is done by cutting tools or lasers performing specific functions on the metal blanks to subtract material from the surface and add holes, cuts, arcs, lines, and other special features to the part.

The process involves written computer code to control the motors and servos of the machine to account for speed, depth, traverse, tool movement, and other parameters required by the part’s design to ensure features remain accurate and the tool stays on its correct course. In addition to higher quality, the computerization and complex code driving the tool’s functions mean the process can be highly automated.

CNC machining relies on a wide range of software to bring a design from concept to completion. Each piece of software adds to the flow of information needed to finish the part. Once this data is complete, it can be loaded into the machine whose computer and controllers will perform the steps in precise order to finish the piece.

Types of CNC Machining Operations

CNC machining is a highly automated manufacturing process suited for a wide variety of industries. Here are the most common CNC machine operations.

Milling

Milling is the process of cutting holes and slots in blank material. Depending on the type of CNC machine, this may be done in different directions and angles. Tools of different shapes and sizes are held within a spindle and rotate to perform the necessary action to create the hole at the required depth.

Turning

During the turning operation, the material is placed in a chuck assembly and rotated at high speed. A tool is then placed in a turret that follows the CNC programming and removes specific amounts of material to reduce, shape, or contour the workpiece. Most turning is done with the tool being stationary while the material rotates. However, more complex CNC machines can perform multiple functions in addition to this, stopping the material spin during turning to complete other tasks.

Grinding

Grinding uses a fast-rotating wheel instead of a fixed tool to remove material from a workpiece. CNC programming software allows the grinding to be done with a high degree of precision. This makes it a handy tool for applications where tight tolerances are required. These tolerances may not have been achievable for the same part produced using manual grinding. CNC grinding is also ideal for parts that need perfect surface finishing. In this case, the grinding tool can polish the finish to high-performance specifications.

Routing

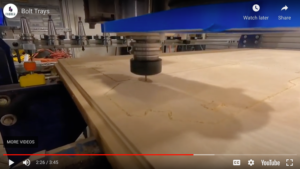

CNC routing is like milling. However, milling may require a hole, a linear cut, a slot, or a simple arc. A router is a specialized tool that cuts long scrolling, molding, or specialty cuts for functional and aesthetic applications. Router heads may place squared or arced cuts in a scroll pattern. They can also make beveled cuts, and for some materials, they can produce mortice and tenon cuts.

Drilling

CNC drilling is more than just the traditional notion of drilling a hole. With CNC drilling, holes can be drilled with precision. They can also be made at accurate depth, and at specific angles within the piece. And finally, they can be precisely made in the exact location called for by the part design. This makes CNC drilling a perfect solution for parts requiring tight tolerances and precision specifications.

The CNC Machining Process: Four Main Steps

The CNC machining process is highly complicated. Several steps must be taken from software to machine execution to take any part from concept through design. Everyone must follow these steps for the process to work. The four main steps for the CNC machining process include:

- Designing the CAD Model – Computer-Aided Design (CAD) allows for the creation and visualization of a design in 2D vector or 3D. It lets designers manipulate lines, curves, arcs, voids, and other internal and external features to create a part design with the correct specifications and geometries. In designing the CAD model, users should be aware that the part must have practical manufacturability so that the features can be correctly rendered in the next step for use in the CNC machine.

- Converting the CAD File to a CNC Program – Once the design has been completed, the next step is to convert the file to a format the machine can use. This may include using Computer-Aided Manufacturing (CAM) software for use in the CNC machine. In CAM software, the CAD file is converted to G-Code, a programming language that specifies each step, motion, speed, and order of the tools to be used to manufacture the part. This code is then ready to be downloaded into the CNC machine, where it will be followed precisely to produce the part.

- Preparing the CNC Machine – Not all workpieces require the same toolsets within the CNC machine. Before the operation, staff must load the blanks or the pre-worked piece into the machine. The securing of the part may include affixing it to chucks, as in the case of turning. It may also require securing in vices or spindles. The type of method used to secure the workpiece will be determined by the tools that are utilized to make it. Once the workpiece is clamped, the operator must ensure that the proper toolset is in place and the correct location within the toolset.

- Executing the Machine Operation – The machine now has the design translated into the proper G-Code and set up to perform the program’s instruction. The G-Code program is entered and acts as a guide, commanding the machine’s movement around the workpiece and each specific action taken by a tool in the correct order.

What is a CNC Machine?

We’ve spent some time on CNC machining and the steps to perform the machining. But what is a CNC machine? A CNC machine is a term used to specify that a computer controls functions to produce parts. Traditionally, machining was done by various equipment such as lathes, drill presses, routers, and other equipment.

By adding computers to these machines, modern manufacturing has sped up the process by using a computer to control the machine’s actions. Today, machines may still be explicitly used for drilling, routing, cutting, or other applications. But the addition and use of a computer to produce fast and more precise parts have revolutionized machining.

In addition to small and straightforward CNC machines, some machines combine the functionality of several of these processes into a single unit. They do this by utilizing multi-axis machines that can turn the tools required at any direction or angle to the workpiece. This includes simple operations such as 2-axis machines for simple holes or cuts through complex and expensive 5-axis machines that can rotate the toolset around the piece in two directions radially.

Types of CNC Machines

Depending on material requirements and end-use, there are many types of CNC machines. They vary depending on the industry and tolerances required for finished parts. Here are a few of the most common types of CNC machines.

Laser Cutters

CNC laser cutters are primarily used in metal or sheet metal applications. Lasers may be fixed while the material moves, or the material may be fixed as the laser itself moves. As the laser cuts the X and Y axis, high-pressure gas is used to remove molten material. Precision is much higher with laser cutting compared to plasma cutting.

Plasma Cutters

Plasma consists of highly heated ionized gas. CNC plasma cutters use this technique to cut metal and other conductive materials. A closed-loop is created by focusing a high-pressure gas down over the workpiece, allowing an electrode near the workpiece to form a conductive path. The plasma follows this path. Molten metal is blown away in the correct path, and the electrode is guided by CNC programming software to remove the material at the desired location on the workpiece.

Waterjet Cutters

CNC waterjet cutters can be used on many materials such as wood, plastic, and rubber. It’s also possible to mix abrasive media with the water to allow cutting of other materials. The structure of some materials is affected by heat machining processes. When using a CNC waterjet, there is no heat component as in laser or plasma, so the structure and strength of edges are not affected. CNC waterjet machines can make precise, complex cut shapes and can even cut stainless and hardened steel. However, they are slower than heat and surface removal processes and have limits in penetration depth.

Milling Machines

CNC milling machines are used in almost every industry. They allow cuts, holes, slots, and other features. Modern machines also have automatic tool changing capability, making them versatile. CNC milling machines are also highly automated, requiring little manual intervention. And they can work with more than metal on materials such as composites, plastics, and ceramics.

Turning Machines

Most people have seen old-fashioned lathes where an operator controls the movement and surface removal of the workpiece manually or with dials and settings. Those limiting features have now been replaced by CNC turning machines. A computer controls the turret that holds the tools to remove material to very tight tolerances. CNC turning machines may have one spindle or two. The two-spindle option allows for automation, and the workpiece can be moved from one spindle to another via instructions from the computer. This allows work to be completed in two axes. Other versions may combine milling and turning in one CNC machine and offer “live tooling” where the workpiece rotation can be stopped to allow milling processes to be performed before continuing its turning cycle.

Routers

CNC routers are used across various industries, including architectural millwork, construction, plastic, foam applications, and many more. They are ideal for complex cutting requirements that require scrolling, beveling, terracing, and other detailed aesthetic or structural requirements. Routing can make squared or arced cuts in a decorative or functional pattern depending on requirements. The control of the CNC by computer allows these cuts to be precise and repeatable.

Electrical Discharge Machines

Electrical Discharge CNC Machines (EDM) are used in metal workpieces for any material that can conduct electricity. EDM uses a spark to cut the workpiece. By submerging the piece in dielectric oil, the material and electrode are insulated, and the spark removes the material as specified by the CNC programming. EDM may also use wire-cutting to create programmed shapes and complex geometries and contours. In these machines, moving wire is guided by the CNC computer acting as the electrode, and the dielectric oil is pumped in between the workpiece and electrode to remove material. Industries requiring complex dies and molds benefit from EDM because the process is burr-free and hardened pieces can be manufactured without heat deformation. It is also ideal for industries with fine, thin, or fragile workpiece features such as fins.

Conclusion

We have described CNC machining in detail and defined what a CNC machine is. We have also given you examples of the types of CNC machines available. These definitions can help understand what application, machine, and process work best for you in this complex process. There are many tools, features, and applications used in CNC machines today.

The path from design to the software application to the cutting and type of machine can produce parts faster and more precisely than in the past.